Production Methods

Metals

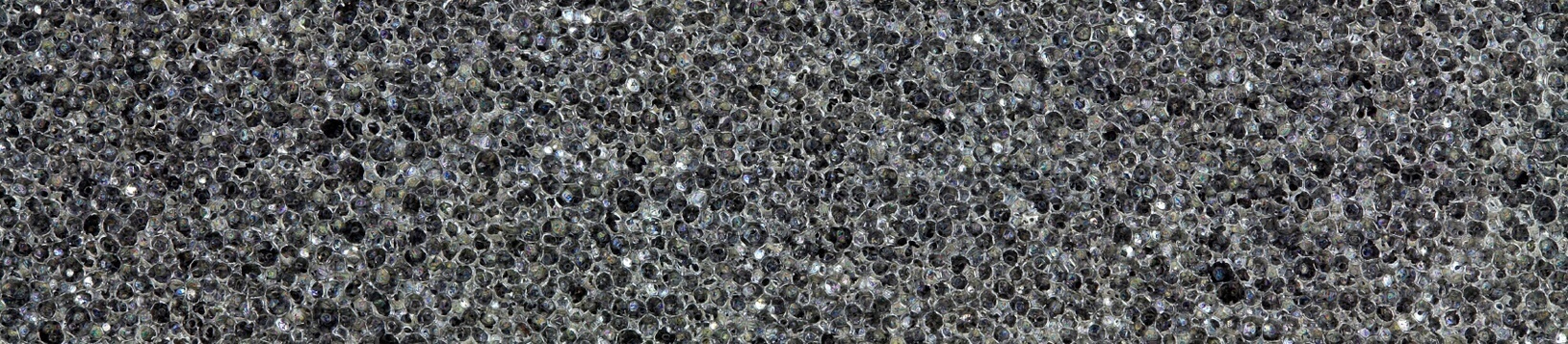

Melt-based methods

Gas Injection

A liquid metallic melt can be foamed by blowing gases (air, nitrogen, argon) using rotating impellers that are responsible for producing gas bubbles in the melt.

Gas-releasing foaming agents

Adding foaming agents to a liquid melt is another method of releasing gas bubbles into the melt. The process is now used in small scale batches.

Solid-gas eutectic solidification (Gasar)

Eutectic systems (or multi-phase systems) formed between liquid metals and hydrogen gas can be used to create a two phase system by reducing temperature and pressures. The process leads to gas entrapment within the solidifying metal.

Investment casting

An indirect method of producing metal foams involves using polymer foam as a starting material in order to form a porous structure by using a reticulation method or foaming method. The polymer foam is filled with a heat resistant material followed by drying and removal of the polymer matrix. Molten metal is then cast into voids to produce a replica of the original foam structure.

Powder-Based Methods

Sintered

The Fraunhofer-Institute process consists of mixing metal powders with a foaming agent, densely compacting the mixture, followed by sintering to obtain the final foam product.

Gas entrapment

Metal powders can also be foamed by compressing powders to a precursor material, then filling the metal compact with gas followed by heating the precursor material to expand the metal due to the entrapped gas. This process is commonly used to make porous titanium structures.

Electrodeposition of Ionized Foams

Ionized foams are made by galvanic electro-deposition. These foams have been tested for use as advanced battery electrode materials.

Ceramics

Chemical vapor deposition (CVD)

Applying ceramic foams as a surface coating uses the process of chemical vapor deposition. Protective or anti-corrosive coatings, for example, are produced using this method.

Foamed Slurry

Either a ceramic powder is mixed to form a slurry with water or organic monomers are mixed with an initiator catalyst to form a slurry. The slurry is then mixed with a foaming agent to create a foam, followed by polymerization, drying and sintering.

Gas-releasing foaming agents

Adding foaming agents to a ceramic slurry or melt is another method of releasing gas bubbles into the melt. The process is now used in small scale batches.

Applications of Foamed Materials

Light, strong structural materials

Aircraft and automobile manufacturers frequently use lightweight strong components consisting of metal or ceramic foam. Lightweight structural materials allow increased fuel efficiency while preserving or even increasing the safety standards of the vehicle.

Filtration

Porous foam membranes are used in filtration of gases and liquids.

Water remediation and absorption of environmental pollutants

Graphene oxide foams are commonly used in water treatment. In addition, spray foams have been used for environmental remediation applications.

Biomedical

Biomedical devices such as implants and orthopedics incorporate foams to allow for the use of biocompatible, but inconveniently heavy materials. For example, titanium foams are currently used in numerous load bearing orthopedic applications.

Lightweight armor

Lightweight armor solutions for various environments such as land, sea, and air often utilizes ceramics, composite materials and metallic foams. Aluminum foam is commonly used for lightweight armor production.

Catalyst Supports

Catalyst supports use foamed ceramic structures to provide large surface areas for catalysis of chemical reactions.

Thermal management

Carbon-based graphite foams are commonly used in heat exchangers and heat sinks.

Vibrational dampening and noise reduction

The noise insulation properties of some foams are used to create sound barriers.

Energy storage - batteries and fuel cells

Recent research has found uses for copper-based foams in advanced energy storage devices such as batteries and fuel cells.

Advanced optical components and mirrors

Lightweight mirrors and advanced optical components utilize foam components for consumer products, defense, and aerospace applications.

Fuel injection & jet engines

Fuel injectors and jet engines use ceramic and metallic foam material components that can withstand high temperatures and pressures while retaining strength.