SECTION 1. IDENTIFICATION

Product Name: Silver Tin Alloy Nanoparticles / Nanopowder

Product Number: All applicable American Elements product codes, e.g. AG-SN-02-NP

, AG-SN-03-NP

, AG-SN-04-NP

, AG-SN-05-NP

CAS #: 12597-76-1

Relevant identified uses of the substance: Scientific research and development

Supplier details:

American Elements

10884 Weyburn Ave.

Los Angeles, CA 90024

Tel: +1 310-208-0551

Fax: +1 310-208-0351

Emergency telephone number:

Domestic, North America: +1 800-424-9300

International: +1 703-527-3887

SECTION 2. HAZARDS IDENTIFICATION

Classification of the substance or mixture

GHS Classification in accordance with 29 CFR 1910 (OSHA HCS)

Eye irritation(Category 2A), H319

Specific target organ toxicity -single exposure(Category 3),

Respiratory system, H335

GHS Label elements, including precautionary statements

Pictogram

Signal word

Warning

Hazard statement(s)

H319

Causes serious eye irritation.

H335

May cause respiratory irritation.

Precautionary statement(s)

P261

Avoid breathing dust/ fume/ gas/ mist/ vapours/ spray.

P264

Wash skin thoroughly after handling.

P271

Use only outdoors or in a well-ventilated area.

P280

Wear eye protection/ face protection.

P304 + P340 + P312

IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing. Call a POISON CENTER or doctor/ physician if you feel unwell.

P305 + P351 + P338

IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P337 + P313

If eye irritation persists: Get medical advice/ attention.

P403 + P233

Store in a well-ventilated place. Keep container tightly closed.

P405

Store locked up.

P501

Dispose of contents/ container to an approved waste disposal plant.

Hazards not otherwise classified (HNOC) or not covered by GHS-none

SECTION 3. COMPOSITION/INFORMATION ON INGREDIENTS

Substances

Formula:

Sn - 7440-31-5

Ag - 7440-22-4

SECTION 4. FIRST AID MEASURES

Description of first aid measures

General advice

Consult a physician. Show this safety data sheet to the doctor in attendance.

If inhaled

If breathed in, move person into fresh air. If not breathing, give artificial respiration. Consult a physician.

In case of skin contact

Wash off with soap and plenty of water. Consult a physician.

In case of eye contact

Rinse thoroughly with plenty of water for at least 15 minutes and consult a physician.

If swallowed

Never give anything by mouth to an unconscious person. Rinse mouth with water. Consult a physician.

Most important symptoms and effects, both acute and delayed

The most important known symptoms and effects are described in the labelling (see section 2) and/or in section 11

Indication of any immediate medical attention and special treatment needed

No data available

SECTION 5. FIREFIGHTING MEASURES

Extinguishing media

Suitable extinguishing media

Use water spray, alcohol-resistant foam, dry chemical or carbon dioxide.

Special hazards arising from the substance or mixture

Tin/tin oxides

Advice for firefighters

Wear self-contained breathing apparatus for firefighting if necessary.

Further information

No data available

SECTION 6. ACCIDENTAL RELEASE MEASURES

Personal precautions, protective equipment and emergency procedures

Use personal protective equipment. Avoid dust formation. Avoid breathing vapours, mist or gas. Ensure adequate ventilation. Evacuate personnel to safe areas. Avoid breathing dust.

For personal protection see section 8.

Environmental precautions

Do not let product enter drains.

Methods and materials for containment and cleaning up

Pick up and arrange disposal without creating dust. Sweep up and shovel. Keep in suitable, closed containers for disposal.

Reference to other sections

For disposal see section 13.

SECTION 7. HANDLING AND STORAGE

Precautions for safe handling

Avoid contact with skin and eyes. Avoid formation of dust and aerosols.

Further processing of solid materials may result in the formation of combustible dusts. The potential for combustible dust formation should be taken into consideration before additional processing occurs.

Provide appropriate exhaust ventilation at places where dust is formed.

For precautions see section 2.

Conditions for safe storage, including any incompatibilities

Keep container tightly closed in a dry and well-ventilated place.

Air and moisture sensitive.

Handle and store under inert gas.

Keep in a dry place.

Storage class (TRGS 510): Non Combustible Solids

Specific end use(s)

Apart from the uses mentioned in section 1 no other specific uses are stipulated

SECTION 8. EXPOSURE CONTROLS/PERSONAL PROTECTION

Exposure controls

Appropriate engineering controls

Handle in accordance with good industrial hygiene and safety practice. Wash hands before breaks and at the end of workday.

Personal protective equipment

Eye/face protection

Safety glasses with side-shields conforming to EN166 Use equipment for eye protection tested and approved under appropriate government standards such as NIOSH (US) or EN 166(EU).

Skin protection

Handle with gloves. Gloves must be inspected prior to use. Use proper glove removal technique (without touching glove's outer surface) to avoid skin contact with this product. Dispose of contaminated gloves after use in accordance with applicable laws and good laboratory practices. Wash and dry hands.

Body Protection

impervious clothing, The type of protective equipment must be selected according to the concentration and amount of the dangerous substance at the specific workplace.

Respiratory protection

For nuisance exposures use type P95 (US) or type P1 (EU EN 143) particle respirator.For higher level protection use type OV/AG/P99 (US) or type ABEK-P2 (EU EN 143) respirator cartridges. Use respirators and components tested and approved under appropriate government standards such as NIOSH (US) or CEN (EU).

Control of environmental exposure

Do not let product enter drains.

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

Information on basic physical and chemical properties

Appearance

Form: powder

Odor

No data available

Odor Threshold

No data available

pH

No data available

Melting point/freezing point

Melting point/range:No data available

No data available

Flash point

Not applicable

Evaporation rate

No data available

Flammability (solid, gas)

No data available

Upper/lower flammability or explosive limits

Lower explosion limit: No data available

Vapor pressure

No data available

Vapor density

No data available

Relative density

No data available

Water solubility

No data available

Partition coefficient: n-octanol/water

No data available

Auto-ignition temperature

No data available

Decomposition temperature

No data available

Viscosity

No data available

Explosive properties

No data available

Oxidizing properties

No data available

Other safety information

No data available

SECTION 10. STABILITY AND REACTIVITY

Reactivity

No data available

Chemical stability

Stable under recommended storage conditions.

Possibility of hazardous reactions

No data available

Conditions to avoid

No data available

Incompatible materials

Strong oxidizing agents, Sulphur compounds, Strong bases, Halogens, Do not store near acids.

Hazardous decomposition products

Other decomposition products-No data available

In the event of fire: see section 5

SECTION 11. TOXICOLOGICAL INFORMATION

Information on toxicological effects

Acute toxicity

No data available

Dermal: No data available

No data available

Skin corrosion/irritation

No data available

Serious eye damage/eye irritation

No data available

Respiratory or skin sensitisation

No data available

Germ cell mutagenicity

No data available

Carcinogenicity

Carcinogenicity-Rat-Implant

Tumorigenic:Equivocal tumorigenic agent by RTECS criteria. Tumorigenic:Tumors at site or application.

Carcinogenicity-Mouse-Implant

Tumorigenic:Equivocal tumorigenic agent by RTECS criteria. Tumorigenic:Tumors at site or application.

IARC:

No component of this product present at levels greater than or equal to 0.1% is identified as

probable, possible or confirmed human carcinogen by IARC.

ACGIH:

No component of this product present at levels greater than or equal to 0.1% is identified as a

carcinogen or potential carcinogen by ACGIH.

NTP:

No component of this product present at levels greater than or equal to 0.1% is identified as a

known or anticipated carcinogen by NTP.

OSHA:

No component of this product present at levels greater than or equal to 0.1% is identified as a

carcinogen or potential carcinogen by OSHA.

Reproductive toxicity

No data available

No data available

Specific target organ toxicity -single exposure

Inhalation-May cause respiratory irritation.

Specific target organ toxicity -repeated exposure

No data available

Aspiration hazard

No data available

Additional Information

RTECS: XP7320000

To the best of our knowledge, the chemical, physical, and toxicological properties have not been thoroughly investigated.

SECTION 12. ECOLOGICAL INFORMATION

Toxicity

Persistence and degradability

No data available

Bioaccumulative potential

No data available

Mobility in soil

No data available

Results of PBT and vPvB assessment

PBT/vPvB assessment not available as chemical safety assessment not required/not conducted

Other adverse effects

No data available

SECTION 13. DISPOSAL CONSIDERATIONS

Waste treatment methods

Product

Offer surplus and non-recyclable solutions to a licensed disposal company.

Contaminated packaging

Dispose of as unused product.

SECTION 14. TRANSPORT INFORMATION

DOT (US)

Not dangerous goods

IMDG

Not dangerous goods

IATA

Not dangerous goods

SECTION 15. REGULATORY INFORMATION

SARA 302 Components

No chemicals in this material are subject to the reporting requirements of SARA Title III, Section 302.

SARA 313 Components

This material does not contain any chemical components with known CAS numbers that exceed the threshold (De Minimis) reporting levels established by SARA Title III, Section 313.

Massachusetts Right To Know Components

Tin

CAS-No.

7440-31-5

Revision Date

1994-04-01

Pennsylvania Right To Know Components

Tin

CAS-No.

7440-31-5

Revision Date

1994-04-01

New Jersey Right To Know Components

Tin

CAS-No.

7440-31-5

Revision Date

1994-04-01

California Prop. 65 Components

This product does not contain any chemicals known to State of California to cause cancer, birth defects, or any other reproductive harm.

SECTION 16. OTHER INFORMATION

Safety Data Sheet according to Regulation (EC) No. 1907/2006 (REACH). The above information is believed to be correct but does not purport to be all inclusive and shall be used only as a guide. The information in this document is based on the present state of our knowledge and is applicable to the product with regard to appropriate safety precautions. It does not represent any guarantee of the properties of the product. American Elements shall not be held liable for any damage resulting from handling or from contact with the above product. See reverse side of invoice or packing slip for additional terms and conditions of sale. COPYRIGHT 1997-2022 AMERICAN ELEMENTS. LICENSED GRANTED TO MAKE UNLIMITED PAPER COPIES FOR INTERNAL USE ONLY.

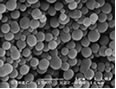

Silver Tin Alloy ( Ag0.035Sn0.965) Nanopowder or Nanoparticles are typically < 150 nanometers (nm) with a BET surface area of > 5.4 m2/g. Nano Silver-tin Alloy Particles are also available in

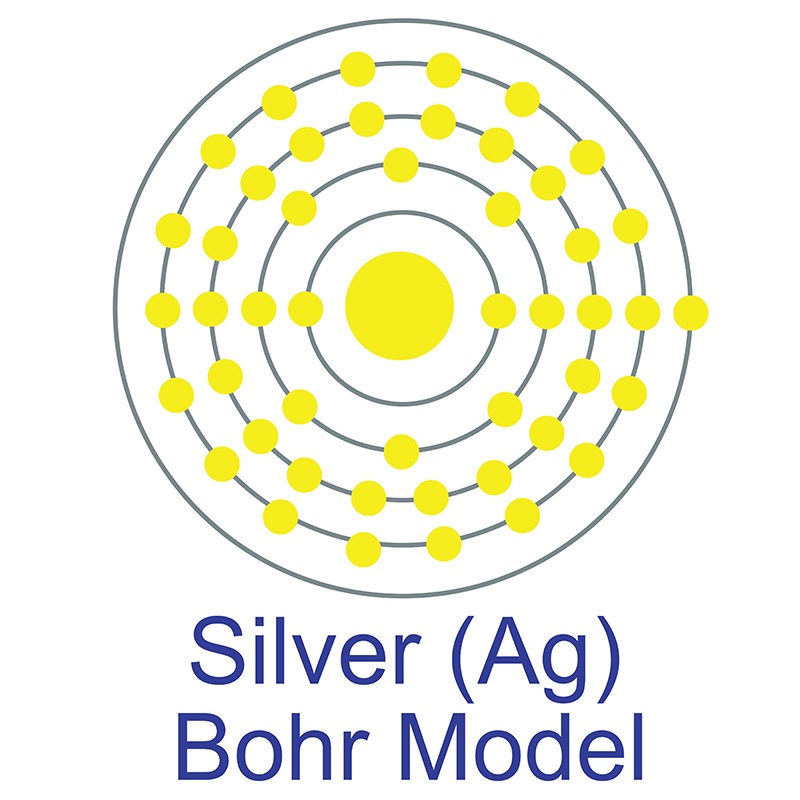

Silver Tin Alloy ( Ag0.035Sn0.965) Nanopowder or Nanoparticles are typically < 150 nanometers (nm) with a BET surface area of > 5.4 m2/g. Nano Silver-tin Alloy Particles are also available in  The number of electrons in each of Silver's shells is 2, 8, 18, 18, 1 and its electron configuration is [Kr]4d10 5s1. The silver atom has a radius of 144 pm and a Van der Waals radius of 203 pm. Silver was first discovered by Early Man prior to 5000 BC. In its elemental form, silver has a brilliant white metallic luster.

The number of electrons in each of Silver's shells is 2, 8, 18, 18, 1 and its electron configuration is [Kr]4d10 5s1. The silver atom has a radius of 144 pm and a Van der Waals radius of 203 pm. Silver was first discovered by Early Man prior to 5000 BC. In its elemental form, silver has a brilliant white metallic luster.  It is a little harder than

It is a little harder than  See more Tin products.

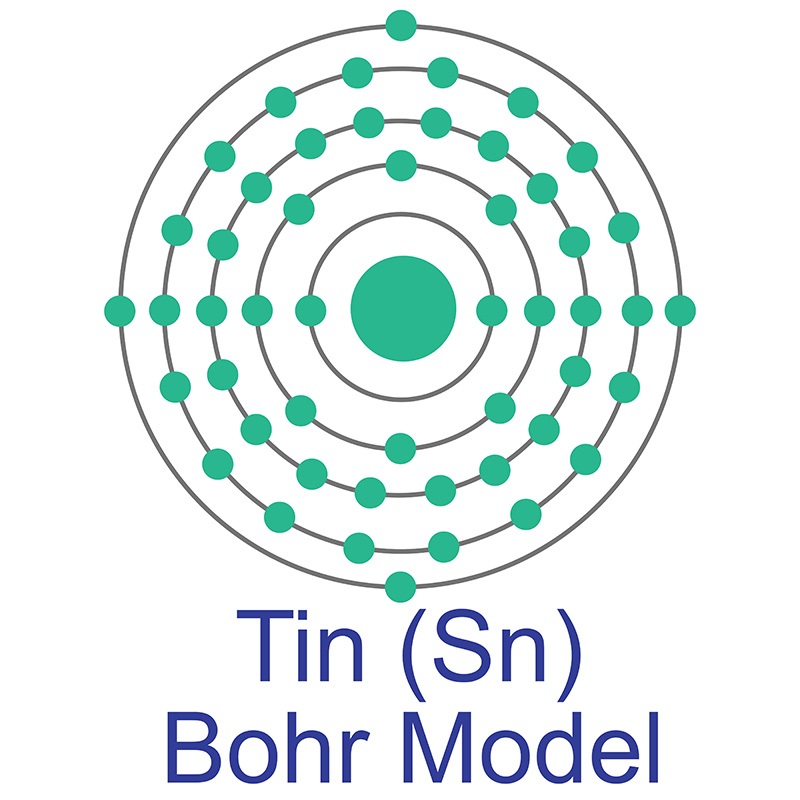

See more Tin products. Tin has nine stable isotopes and 18 unstable isotopes. Under 3.72 degrees Kelvin, Tin becomes a superconductor. Applications for tin include

Tin has nine stable isotopes and 18 unstable isotopes. Under 3.72 degrees Kelvin, Tin becomes a superconductor. Applications for tin include