SECTION 1. IDENTIFICATION

Product Name: Tin Sulfate Solution

Product Number: All applicable American Elements product codes, e.g. SN-SAT-02-SOL

, SN-SAT-03-SOL

, SN-SAT-04-SOL

, SN-SAT-05-SOL

CAS #: 7488-55-3

Relevant identified uses of the substance: Scientific research and development

Supplier details:

American Elements

10884 Weyburn Ave.

Los Angeles, CA 90024

Tel: +1 310-208-0551

Fax: +1 310-208-0351

Emergency telephone number:

Domestic, North America: +1 800-424-9300

International: +1 703-527-3887

SECTION 2. HAZARDS IDENTIFICATION

Classification (GHS-US)

Skin Corr. 1A H314

Carc. 1A H350

Signal word (GHS-US):

Danger

Hazard statements (GHS-US):

H314 - Causes severe skin burns and eye damage

H350 - May cause cancer

Precautionary statements (GHS-US):

P201 - Obtain special instructions before use

P202 - Do not handle until all safety precautions have been read and understood

P260 - Do not breathe mist/vapors/spray

P264 - Wash hand and other exposed areas thoroughly after handliong

P280 - Wear protective gloces/protective clothing/ eye protection/ face protection

P301+P330+P331 - IF SWALLOWED : rinse mouth. Do NOT induce vomiting

P303+P361+P353 - IF ON SKIN (or hair): Remove/ Take off immediately all contaminated clothing. Rinse skin with water/shower

P304+P340 - IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing

P305+P351+P338 - If in eyes: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing

P308+P313 - If exposed or concerned:Get medical advice/attention

P337+P313 - If eye irritation persists: Get medical advice/ attention

P363 - Wash contaminated clothing before reuse

Other Hazards

Strong inorganic acid mists containing sulfuric acid are classified as a known human carcinogen. This classification does not apply to sulfuric acid solutions.

Unknown acute toxicity (GHS-US)

None of the ingredients in the mixture are of unknown toxicity

SECTION 3. COMPOSITION/INFORMATION ON INGREDIENTS

Substance

N/A - product is a mixture

Mixture

Sulfuric Acid

CAS: 7664-93-9

0-2%

GHS-US

Skin Corr. 1A, H314

Carc. 1A, H350

Sulfuric Acid, Tin(II) Salt

CAS: 7488-55-3

15-25%

GHS-US

Not classified

SECTION 4. FIRST AID MEASURES

Swallowing:

Do NOT induce vomiting. Give large quantities of water. Call a physician. Do NOT neutralize the acid. Never give anything by mouth to an unconscious person.

Inhalation:

If inhaled, remove to fresh air immediately and have patient lie down if breathing is difficult. Call a physician.

Eyes/Skin:

IMMEDIATEDLY (within seconds) flush eyes or skin with plenty of water. Promptly get

medical help – apply compresses of iced water if there is a delay before medical treatment

SECTION 5. FIREFIGHTING MEASURES

Flashpoint (oF):

N/A

Flammable limits in air

LOWER: N/A UPPER: N/A

Extinguishing media:

Water, fog, foam

Special firefighting method:

Wear SCBA if fumes or mists are present

Unusual fire and explosion hazards:

Neutralize run-off with lime, soda ash, etc. Hydrogen gas formation is possible.

SECTION 6. ACCIDENTAL RELEASE MEASURES

Steps to be taken if material is released or spilled:

Soak up small spills with sand, clay or distomoceous earth.

Neutralize large spills with lime or soda ash and transfer to a waste water treatment system.

Waste disposal method:

Cleaned-up material may be a RCRA hazardous waste on disposal. Do not flush to surface water or sanitary sewer system. Dispose of in accordance with all local, state, and federal regulations.

SECTION 7. HANDLING AND STORAGE

Precautions to be taken in handling and storage:

Keep out of sun and away from heat, sparks and flame.

Loosen closure carefully.

Other precautions:

Do not wash out container or use it for other purposes; replace closure after each withdrawal.

SECTION 8. EXPOSURE CONTROLS/PERSONAL PROTECTION

Sulfuric Acid, Tin(II) Salt

CAS: 7488-55-3

USA ACGIH

ACGIH TWA (mg/m3)

2mg/m3 (Tin)

USA OSHA

OSHA PEL (TWA) (mg/m3)

2mg/m3 (Tin)

Sulfuric Acid

CAS: 7664-93-9

USA ACGIH

ACGIH TWA (mg/m3)

0.2mg/m3

USA OSHA

OSHA PEL (TWA) (mg/m3)

1mg/m3

Appropriate Engineering Controls: Ensure tha eyewash station and safety showers are close to the workstation location.

Personal Protective equipment: Avoid all unnecessary exposure.

Hand Protection: Wear protective gloves.

Eye Protection: Chemical goggles or face shield

Skin and body protection: Wear suitable protective clothing.

Respiratory Protection: Not typically required if exposures are below established limits. If needed, use NIOS appproved respirator.

Other information: Do not eat, drink or smoke during use.

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

Boiling Point (oF @ 760 mmHg): > 212

Specific gravity (H2O = 1 @ 72oF): 1.210

Solubility in water: Complete

Evaporation rate (butyl acetate = 1): > 1

SECTION 10. STABILITY AND REACTIVITY

Stability considerations/Conditions to avoid:

Stable / Water, organic materials (potential violent reaction, heat)

Hazardous polymerization/Conditions to avoid:

Will not occur / None

Incompatibility/Conditions to avoid:

Alkaline solutions, metals. Strong oxidizing, reducing or combustible organic materials.

Hazardous combustion or Decomposition products:

Hazardous gases may be generated on contact with cyanides, sulfides and carbides.

SECTION 11. TOXICOLOGICAL INFORMATION

Acute toxicity: Not classified

Sulfuric Acid

CAS: 7664-93-9

LD50 oral rat: 2140 mg/kg

LC50 inhalation rat: 510 mg/m3 (Exposure time:2 h)

Skin Corrosion/irritation: Causes severe skin burns and eye damage

Serious eye damage/irritation: Causes serious eye damage

Respiratory or Skin sentization: Not Classified

Germ cell mutagenicity: Not Classified

Carcinogenicity: May cause cancer in mist form

Sulfuric Acid

CAS: 7664-93-9

IARC group

1 - Carcinogenic to humans (only "strong inorganic acid mists containing sulfuric acid")

Reproductive toxicity: Not Classified

Specific target organ toxicity (single exposure): Not classified

Specific target organ toxicity (repeated exposure): Not classified

Aspiration hazard: Not classified

Potantial Adverse Human health effects and symptoms: No additonal infomation available

Symptoms/injuries If inhaled: May cause cancer by Inhalation

Symptoms/injuries In case of eye contact: causes serious eye irritation

SECTION 12. ECOLOGICAL INFORMATION

Toxicity

Sulfuric Acid

CAS: 7664-93-9

LC50 fish 1 > 500mg/l (Exposure time: 96 h - Species: Brachydanio rerio [static])

Persistence and degradability:

Not established

Bioaccumulative potential:

Stannous Sulfate Solution

Not established

Sulfuric Acid

BCF fish 1 (no bioaccumulation)

Mobility in soil:

No additional information available

Other adverse effects

Other information: Avoid release to the environment

SECTION 13. DISPOSAL CONSIDERATIONS

Waste disposal recommendations: Dispose in a safe manner in accordance with local, state, and federal regulations

Ecology - waste materials: Avoid release to the environment.

SECTION 14. TRANSPORT INFORMATION

Department of Transportation: Domestic Ground

Proper shipping name: Corrosive Liquid, N.O.S.

Hazard Class: 8

ID & Packing Group Number: UN 1760, PG III

ERG Guide Number: 154

SECTION 15. REGULATORY INFORMATION

SARA Title III Program Section 313 Supplier Notifica

tion. This product contains the following toxic

chemicals:

Chemical Name CAS Number Concentration

Sulfuric Acid 7664-93-9 < 20%

State Right-to-Know Programs

Pennsylvania: This product contains the following chemicals listed in PA Code Title 34,

Hazardous Substance List: Sulfuric Acid

California: This product contains the following compounds subject to the reporting and

labeling requirements of Proposition 65: None

SECTION 16. OTHER INFORMATION

Safety Data Sheet according to Regulation (EC) No. 1907/2006 (REACH). The above information is believed to be correct but does not purport to be all inclusive and shall be used only as a guide. The information in this document is based on the present state of our knowledge and is applicable to the product with regard to appropriate safety precautions. It does not represent any guarantee of the properties of the product. American Elements shall not be held liable for any damage resulting from handling or from contact with the above product. See reverse side of invoice or packing slip for additional terms and conditions of sale. COPYRIGHT 1997-2022 AMERICAN ELEMENTS. LICENSED GRANTED TO MAKE UNLIMITED PAPER COPIES FOR INTERNAL USE ONLY.

See more Tin products.

See more Tin products. Tin has nine stable isotopes and 18 unstable isotopes. Under 3.72 degrees Kelvin, Tin becomes a superconductor. Applications for tin include

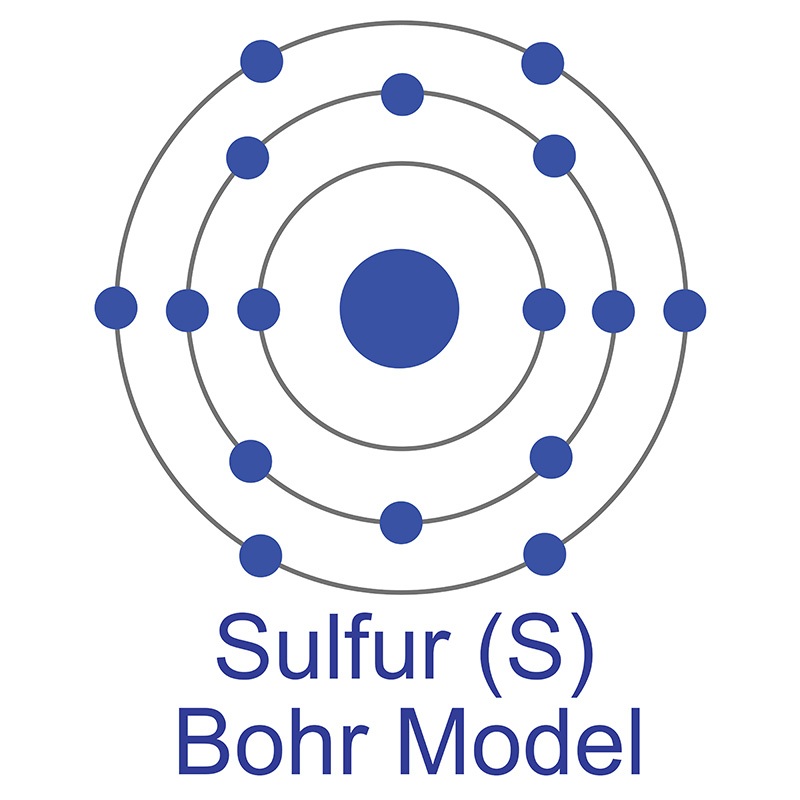

Tin has nine stable isotopes and 18 unstable isotopes. Under 3.72 degrees Kelvin, Tin becomes a superconductor. Applications for tin include  The number of electrons in each of Sulfur's shells is 2, 8, 6 and its electron configuration is [Ne] 3s2 3p4. In its elemental form, sulfur has a light yellow appearance. The sulfur atom has a covalent radius of 105 pm and a Van der Waals radius of 180 pm. In nature, sulfur can be found in hot springs, meteorites, volcanoes, and as galena, gypsum, and epsom salts. Sulfur has been known since ancient times but was not accepted as an element until 1777, when Antoine Lavoisier helped to convince the scientific community that it was an element and not a compound.

The number of electrons in each of Sulfur's shells is 2, 8, 6 and its electron configuration is [Ne] 3s2 3p4. In its elemental form, sulfur has a light yellow appearance. The sulfur atom has a covalent radius of 105 pm and a Van der Waals radius of 180 pm. In nature, sulfur can be found in hot springs, meteorites, volcanoes, and as galena, gypsum, and epsom salts. Sulfur has been known since ancient times but was not accepted as an element until 1777, when Antoine Lavoisier helped to convince the scientific community that it was an element and not a compound.