American Elements adheres to the highest standards across all aspects of our manufacturing, including GMP and LEAN Sigma documented processes where applicable. American Elements production SOPs follow ISO 9002 documentary standards to assure the strictest level of in-process production tracking and control. We are in full compliance with the requirements of the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) to assure uninterrupted service of our products to our customers within the European Union/European Economic Area (EU/EEA).

Our production meets all ASTM and industry-specific standards such as IATF 16949 and CGMP regulations. Our dedication to the highest possible quality control and lot-to-lot consistency is equally matched by our goal to be at the forefront of creating a sustainable planet that continually moves towards improving the human experience for all mankind. Invention is the means of achieving this goal, and American Elements employees are driven to engineer and deliver the basic raw materials of innovation in a socially responsible manner.

Manufacturing QA/QC

The following outlines how American Elements' QA controls ensure the highest quality of our manufactured products:

- Process Controls – QA manages all processes to ensure consistent quality and improve procedures when it is necessary. Failure Mode & Effects Analysis (FMEA) is applied during product and process development.

- Document Control – QA ensures only approved and up-to-date documents are used. All document revisions and manufacturing activities are traceable and documented.

- Traceability of raw materials, finished goods, defects – QA tracks all details - documentation, testing, and movement of all materials used for production. Finished goods are tracked based on production processes. Any production defect can be traced down to date, operator, and equipment used.

- CAPA – Possible nonconformities are identified and avoided ahead of time using trend analysis. Any new deviation or nonconformance is investigated following the 8D problem solving process. Corrective and preventative actions are documented, implemented and communicated to the customer where applicable.

Testing Standards & Methods

In addition to providing certification and testing for American Elements' own materials, our laboratories have for many years provided contract testing for our customers. Customers as large as Fortune 100 companies have at times found that it is more cost-effective to allow us to perform specialized analyses rather than shouldering the cost of establishing their own laboratory.

Our highly qualified personnel, many of whom have held management positions at leading research labs, including General Electric’s Center for Research and Development (GE CRD) and Bell Labs, perform all analysis on validated instrumentation. Our analytical capabilities are available at all stages of product development, from testing of raw materials, in-process quality control, and performance testing of processed materials and final products. We provide complete analytical support, which can include consulting on development of specifications and process controls.

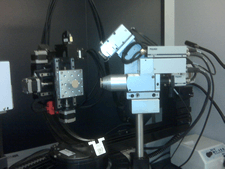

American Elements' operations are supported by state-of-the-art research and analytical laboratory facilities, including chemical analysis by AA, ICP, and XRF; crystal and phase structure analysis by X-Ray diffraction; and particle morphology by SEM, BET specific surface area analysis, and particle distribution analysis. Our advanced ceramic powders can be tested and certified on a plethora of additional performance basis, including among them strength, density, stability, flowability and ionic or electric conductivity/resistivity.

The following analytical capabilities are available on a one time or contract basis. While our laboratories are primarily dedicated to our own product testing, we usually maintain capacity for quick turn-around analysis, and we are able to charge less than most contract laboratories.

Full list of available services:

- Spectroscopy:

- Atomic

- X-ray fluorescence

- Infrared

- Classical wet chemistry

- Separations

- Precipitation

- Extractions

- Distillation

- Quantitative Analyses

- Gravimetric

- Volumetric (titrations)

- Qualitative Analyses

- Melting point determination

- Flame test

- Select other chemical tests by request

- Physical / Structural Analyses

- Particle size distribution analysis

- Powder surface area analysis

- Solid and liquid density calculation

- Viscosity/rheology analysis

- Gas chromatography

- SEM/EDX

- Surface structure analysis

- Particle morphology

- Fracture analysis

- Strength Analyses

- Crush strength

- Green body strength

- Sintered body strength

- 4-point bending strength (bars)

- Closed and open porosity

- X-ray diffraction for phase identification

- Thermal Analysis

- Differential scanning calorimetry (DSC)

- Thermogravimetric analysis (TGA)

- Thermomechanical analysis (TMA)

- Dilatometry (TCE)

- Electrical Measurements

- Dielectric constant measurement

- Accelerated life test (HALT)

- Temperature coefficient of capacitance (TCC)

- Insulation resistance (IR)

- Electrical failure analysis

- 4-lead resistance

- 2-lead resistance

Safety Protocols

American Elements conducts safety training in compliance with all mandatory OSHA standards including workplace safety, materials handling and storage, transportation, and emergency response. Employees undergo regular training sessions to ensure competence in all SOP's applicable to their position.

Process Audits

In accordance with strict Safety, Health and Environmental Management practices, American Elements conducts regular audits of all internal departments and external suppliers on a scheduled basis. Additionally, we are capable of performing audits upon customer request.

Corporate Quality Policy

American Elements' mission is to provide customers with comprehensive material science knowledge and support. The key to success in fulfilling this mission is a total commitment to continuous quality improvement across the organization. American Elements constantly seeks to exceed its clients' and customers' expectations, using procedures and processes that are reliable, efficient and economical. American Elements employees are encouraged to develop their knowledge and skills to deliver the best possible service at all times. American Elements’ goal is to excel in everything it does by embracing the need for continuous improvement and innovation.

American Elements is performance driven. This entails verifying that all our products and services meet agreed requirements. We will monitor, benchmark and continuously improve our business, products and services, organization and employees’ performance. Overall, we strive to consistently deliver a superior product with superior service.

American Elements