SECTION 1. IDENTIFICATION

Product Name: Titanium Powder

Product Number: All applicable American Elements product codes, e.g. TI-M-02-P

, TI-M-03-P

, TI-M-04-P

, TI-M-05-P

CAS #: 7440-32-6

Relevant identified uses of the substance: Scientific research and development

Supplier details:

American Elements

10884 Weyburn Ave.

Los Angeles, CA 90024

Tel: +1 310-208-0551

Fax: +1 310-208-0351

Emergency telephone number:

Domestic, North America: +1 800-424-9300

International: +1 703-527-3887

SECTION 2. HAZARDS IDENTIFICATION

Classification of the substance or mixture

Classification according to Regulation (EC) No 1272/2008

GHS02 Flame

Flam. Sol. 1 H228 Flammable solid.

Hazards not otherwise classified

No data available.

Label elements

Labelling according to Regulation (EC) No 1272/2008

The product is classified and labeled according to the CLP regulation.

Hazard pictograms

GHS02

Signal word

Danger

Hazard statements

H228 Flammable solid.

Precautionary statements

P210 Keep away from heat/sparks/open flames/hot surfaces. - No smoking.

P280 Wear protective gloves/protective clothing/eye protection/face protection.

P240 Ground/bond container and receiving equipment.

P241 Use explosion-proof electrical/ventilating/lighting/equipment.

P370+P378 In case of fire: Use for extinction: CO2, powder or water spray.

WHMIS classification

B4 - Flammable solid

Classification system

HMIS ratings (scale 0-4)

(Hazardous Materials Identification System)

HEALTH

FIRE

REACTIVITY

1

2

2

Health (acute effects) = 1

Flammability = 2

Physical Hazard = 2

Other hazards

Results of PBT and vPvB assessment:

PBT:

N/A.

vPvB:

N/A

SECTION 3. COMPOSITION/INFORMATION ON INGREDIENTS

Chemical characterization: Mixtures

Dangerous components:

7440-32-6 Titanium

Self-heat. 1, H251 70.0%

Additional information

None known.

Non-Hazardous Ingredients

7732-18-5 Water 30.0%

SECTION 4. FIRST AID MEASURES

Description of first aid measures

If inhaled:

Supply fresh air. If not breathing, provide artificial respiration. Keep patient warm.

Seek immediate medical advice.

In case of skin contact:

Immediately wash with soap and water; rinse thoroughly.

Seek immediate medical advice.

In case of eye contact:

Rinse opened eye for several minutes under running water. Consult a physician.

If swallowed:

Seek medical treatment.

Information for doctor

Most important symptoms and effects, both acute and delayed

No information available.

Indication of any immediate medical attention and special treatment needed

No information available.

SECTION 5. FIREFIGHTING MEASURES

Extinguishing media

Suitable extinguishing media

Special powder for metal fires. Do not use water.

For safety reasons unsuitable extinguishing media

Water

Special hazards arising from the substance or mixture

If this product is involved in a fire, the following can be released:

Titanium oxides

Advice for firefighters

Protective equipment:

Wear self-contained respirator.

Wear fully protective impervious suit.

SECTION 6. ACCIDENTAL RELEASE MEASURES

Personal precautions, protective equipment and emergency procedures

Wear protective equipment. Keep unprotected persons away.

Ensure adequate ventilation

Keep away from ignition sources

Environmental precautions:

Do not allow product to reach sewage system or any water course.

Methods and material for containment and cleanup:

Ensure adequate ventilation.

Prevention of secondary hazards:

Keep away from ignition sources.

Reference to other sections

See Section 7 for information on safe handling

See Section 8 for information on personal protection equipment.

See Section 13 for disposal information.

SECTION 7. HANDLING AND STORAGE

Handling

Precautions for safe handling

Keep container tightly sealed.

Store in cool, dry place in tightly closed containers.

Ensure adequate ventilation.

Information about protection against explosions and fires:

Protect against electrostatic charges.

Conditions for safe storage, including any incompatibilities

Storage

Requirements to be met by storerooms and receptacles:

Store in a cool location.

Information about storage in one common storage facility:

No data available.

Further information about storage conditions:

Keep container tightly sealed.

Store in cool, dry conditions in well-sealed containers.

Specific end use(s)

No information available.

SECTION 8. EXPOSURE CONTROLS/PERSONAL PROTECTION

Additional information about design of technical systems:

Properly operating chemical fume hood designed for hazardous chemicals and having an average face velocity of at least 100 feet per minute.

Control parameters

Components with limit values that require monitoring at the workplace:

The product does not contain any relevant quantities of materials with critical values that should be monitored at the workplace.

Additional information:

No data

Exposure controls

Personal protective equipment

Follow typical general protective and industrial hygiene measures for handling chemicals.

Keep away from foodstuffs, beverages and feed.

Remove all soiled and contaminated clothing immediately.

Wash hands before breaks and at the end of work.

Breathing equipment:

Use suitable respirator when high concentrations are present.

Recommended filter device for short term use:

Use a respirator with type N95 (USA) or PE (EN 143) cartridges as a backup to engineering controls. Risk assessment should be performed to determine if air-purifying respirators are appropriate. Only use equipment tested and approved under appropriate government standards.

Protection of hands:

Impervious gloves

Inspect gloves prior to use.

Suitability of gloves should be determined both by material and quality, the latter of which may vary by manufacturer.

Material of gloves

Nitrile rubber, NBR

Penetration time of glove material (in minutes)

480

Glove thickness

0.11 mm

Eye protection:

Safety glasses

Body protection:

Protective work clothing

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

Information on basic physical and chemical properties

Appearance:

Form: Powder in water

Color: Dark gray

Odor: Odorless

Odor threshold: No data available.

pH: N/A.

Melting point/range: No data available.

Boiling point/range: No data available.

Sublimation temperature / start: No data available.

Flammability (solid, gas):

Highly flammable

Ignition temperature: No data available.

Decomposition temperature: No data available.

Auto igniting: Product is not selfigniting.

Danger of explosion: No data available.

Explosion limits:

Lower: No data available.

Upper: No data available.

Vapor pressure: N/A.

Density: No data available.

Relative density

No data available.

Vapor density

N/A.

Evaporation rate

N/A.

Solubility in Water (H2O): Insoluble

Partition coefficient (n-octanol/water): No data available.

Viscosity:

Dynamic: N/A.

Kinematic: N/A.

Solvent content:

Organic solvents: 0.0 %

Solids content: 70.0 %

Other information

No information available.

SECTION 10. STABILITY AND REACTIVITY

Reactivity

No data available.

Chemical stability

Stable under recommended storage conditions.

Thermal decomposition / conditions to be avoided:

Decomposition will not occur if used and stored according to specifications.

Possibility of hazardous reactions

No dangerous reactions known

Conditions to avoid

No information available.

Incompatible materials:

No data available.

Hazardous decomposition products:

Titanium oxides

SECTION 11. TOXICOLOGICAL INFORMATION

Information on toxicological effects

Acute toxicity:

N/A

LD/LC50 values that are relevant for classification:

No data

Skin irritation or corrosion:

May cause irritation

Eye irritation or corrosion:

May cause irritation

Sensitization:

No sensitizing effects known.

Germ cell mutagenicity:

N/A

Carcinogenicity:

The Registry of Toxic Effects of Chemical Substances (RTECS) contains tumorigenic and/or carcinogenic and/or neoplastic data for components in this product.

No classification data on carcinogenic properties of this material is available from the EPA, IARC, NTP, OSHA or ACGIH.

Reproductive toxicity:

The Registry of Toxic Effects of Chemical Substances (RTECS) contains reproductive data for components in this product.

Specific target organ system toxicity - repeated exposure:

N/A

Specific target organ system toxicity - single exposure:

N/A

Aspiration hazard:

N/A

Subacute to chronic toxicity:

N/A

Additional toxicological information:

To the best of our knowledge the acute and chronic toxicity of this substance is not fully known.

Carcinogenic categories

OSHA-Ca (Occupational Safety & Health Administration)

None of the ingredients is listed

SECTION 12. ECOLOGICAL INFORMATION

Toxicity

Aquatic toxicity:

No information available.

Persistence and degradability:

No information available.

Bioaccumulative potential:

No information available.

Mobility in soil:

No information available.

Additional ecological information:

General notes:

Avoid transfer into the environment.

Results of PBT and vPvB assessment:

PBT:

N/A.

vPvB:

N/A.

Other adverse effects

No information available.

SECTION 13. DISPOSAL CONSIDERATIONS

Waste treatment methods

Recommendation:

Consult state, local or national regulations to ensure proper disposal.

Uncleaned packagings:

Recommendation:

Disposal must be made according to official regulations.

SECTION 14. TRANSPORT INFORMATION

UN-Number

DOT, IMDG, IATA

UN1352

UN proper shipping name

DOT

Titanium powder, wetted

IMDG, IATA

TITANIUM POWDER, WETTED

Transport hazard class(es)

DOT

Class

4.1 Flammable solids, self-reactive substances and solid desensitised explosives.

Label

4.1

Class

4.1 (F3) Flammable solids, self-reactive substances and solid desensitised explosives

Label

4.1

IMDG, IATA

Class

4.1 Flammable solids, self-reactive substances and solid desensitised explosives.

Label

4.1

Packing group

DOT, IMDG, IATA

II

Environmental hazards:

Marine pollutant (IMDG):

No

Special precautions for user

Warning: Flammable solids, self-reactive substances and solid desensitised explosives

EMS Number: F-A,S-J

Segregation groups

Powdered metals

Transport in bulk according to Annex II of MARPOL73/78 and the IBC Code

N/A.

Transport/Additional information:

DOT

Marine Pollutant (DOT):

No

UN "Model Regulation":

UN1352, Titanium powder, wetted, 4.1, Il

SECTION 15. REGULATORY INFORMATION

Safety, health and environmental regulations/legislation specific for the substance or mixture

National regulations

All components of this product are listed in the U.S. Environmental Protection Agency Toxic Substances Control Act Chemical substance Inventory.

All components of this product are listed on the Canadian Domestic Substances List (DSL).

SARA Section 313 (specific toxic chemical listings)

None of the ingredients are listed.

California Proposition 65

Prop 65 - Chemicals known to cause cancer

None of the ingredients are listed.

Prop 65 - Developmental toxicity

None of the ingredients are listed.

Prop 65 - Developmental toxicity, female

None of the ingredients are listed.

Prop 65 - Developmental toxicity, male

None of the ingredients are listed.

Information about limitation of use:

For use only by technically qualified individuals.

Other regulations, limitations and prohibitive regulations

Substance of Very High Concern (SVHC) according to the REACH Regulations (EC) No. 1907/2006.

None of the ingredients are listed.

The conditions of restrictions according to Article 67 and Annex XVII of the Regulation (EC) No 1907/2006 (REACH) for the manufacturing, placing on the market and use must be observed.

None of the ingredients is listed.

Annex XIV of the REACH Regulations (requiring Authorisation for use)

None of the ingredients is listed.

Chemical safety assessment:

A Chemical Safety Assessment has not been carried out.

SECTION 16. OTHER INFORMATION

Safety Data Sheet according to Regulation (EC) No. 1907/2006 (REACH). The above information is believed to be correct but does not purport to be all inclusive and shall be used only as a guide. The information in this document is based on the present state of our knowledge and is applicable to the product with regard to appropriate safety precautions. It does not represent any guarantee of the properties of the product. American Elements shall not be held liable for any damage resulting from handling or from contact with the above product. See reverse side of invoice or packing slip for additional terms and conditions of sale. COPYRIGHT 1997-2022 AMERICAN ELEMENTS. LICENSED GRANTED TO MAKE UNLIMITED PAPER COPIES FOR INTERNAL USE ONLY.

American Elements specializes in producing high purity Titanium Powder with the smallest possible average grain sizes for use in preparation of pressed and bonded sputtering targets and in Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) processes including Thermal and Electron Beam (E-Beam) Evaporation, Low Temperature Organic Evaporation, Atomic Layer Deposition (ALD),

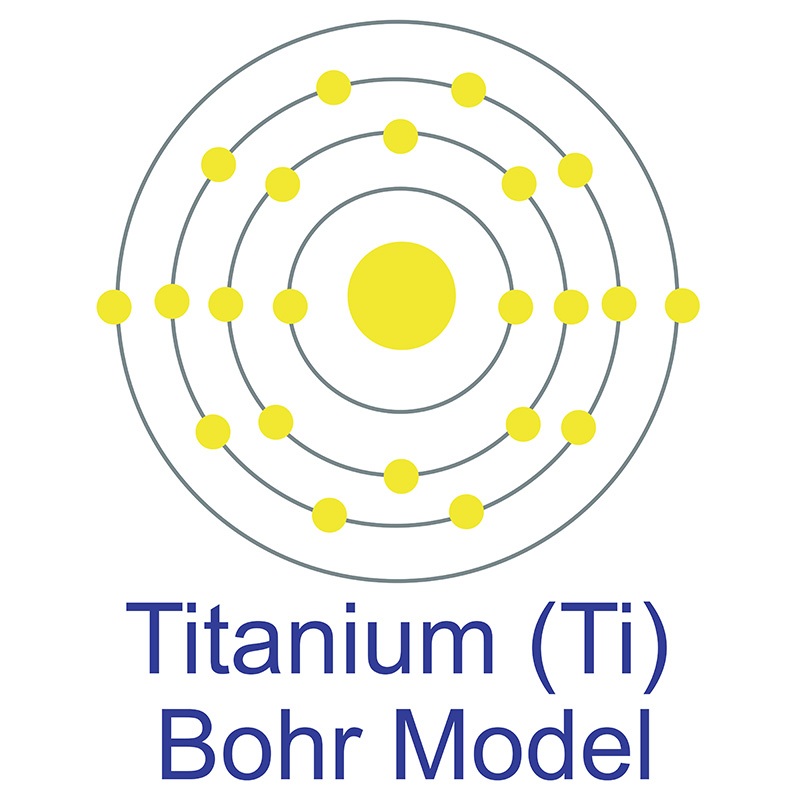

American Elements specializes in producing high purity Titanium Powder with the smallest possible average grain sizes for use in preparation of pressed and bonded sputtering targets and in Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) processes including Thermal and Electron Beam (E-Beam) Evaporation, Low Temperature Organic Evaporation, Atomic Layer Deposition (ALD),  The titanium atom has a radius of 147 pm and a Van der Waals radius of 187 pm. Titanium was discovered by William Gregor in 1791 and first isolated by Jöns Jakob Berzelius in 1825. In its elemental form, titanium has a silvery grey-white metallic appearance. Titanium's properties are chemically and physically similar to

The titanium atom has a radius of 147 pm and a Van der Waals radius of 187 pm. Titanium was discovered by William Gregor in 1791 and first isolated by Jöns Jakob Berzelius in 1825. In its elemental form, titanium has a silvery grey-white metallic appearance. Titanium's properties are chemically and physically similar to  Titanium has five naturally occurring

Titanium has five naturally occurring